AK Industrial Services combines speed with precision to deliver fast, accurate coating and membrane removal for your projects.

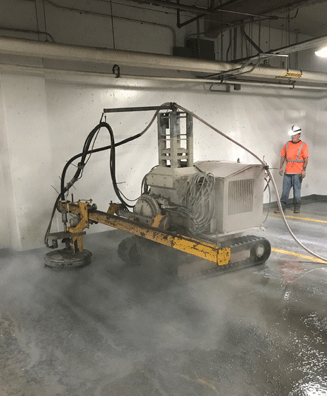

Using equipment customized to suit several applications, the AK Industrial Services team provides hydro coating and membrane removal as a versatile solution for use on all concrete, asphalt, and metal surfaces. Our specialized pressure-compensated pump allows us to reduce the water volume through the applicator while increasing the pressure, to limit waste.

When you need coating removal, whether it’s paint, a specialized coating, or virtually any epoxy, AK Industrial Services has the solution. With up to 55K PSI, we can provide non-destructive, ultra-high pressure (UHP) water jetting that will safely remove every trace of coating without damaging the surface. This provides you with a clean, drastically-improved anchoring surface, and an excellent base that’s ready for new coatings.

Types of Coating and Membrane Removal Include:

- Lead paint abatement

- Steel preparation

- PCB and lead contamination removal

- Epoxy coating removal

- Paint removal

- Membrane removal

- Rubber removal on runways

- Removal of paint from concrete and asphalt

Coating Removal for Every Surface

Coating and membrane removal quickly and effectively prepares base materials for receiving new base and finish coatings. Unlike other coating removal processes, hydro coating removal selectively removes coatings such as paints, epoxies, and urethanes without damaging the surface. Additionally, coating removal from AK Industrial Services provides a far superior anchoring pattern compared to shot blast, so the surface repair lasts longer, saving you more in the long run. more

Water Jetting as a Superior Solution for Coating & Membrane Removal

With mechanical coating removal tools such as grinders or milling machines, you spend more time cleaning up and repairing the surface because these tools cause damage and actually remove part of the surface in the process of removing the coating. Conversely, tools such as sand blasters have a hard time getting the job done. Water jetting is the ideal alternative, as it delivers the power needed to quickly remove surface coating, with precise control that enables our team to remove only what you need removed.

Hydro Blasting Coating Removal by AK Industrial Services

Some call it hydro blasting, others call it water blasting, and you might also hear it called hydro cleaning. Regardless of what you call it, the ability to propel water at ultra-high pressure and speed, coupled with the AK Industrial Services team’s experience, delivers the solutions that your projects need.

Our investment in qualified technicians, state of the art equipment, and custom-built hydro blasting tools means that AK Industrial Services is capable of providing the power and precision needed to suit an extremely wide variety of applications, on virtually any surface.

The Flexibility and Power of Hydro Blasting Make It The Ideal Solution For:

- Pavement maintenance

- Stripe removal

- Coating removal

- Hazardous coating removal

- Runway rubber removal

- Surface preparation

- Marine surface prep

- Sandstone texturing

- Chloride removal from concrete

- Residue removal

- Brick and concrete restoration

- Removal of mill scale deposits

- Calcide removal

- Rust and sludge removal from boilers, pipes, emission tubes, heat exchangers, condensers, and tanks

AK Industrial Services has developed custom components and nozzles that allow for varying flow rates and speeds, to ensure that we deliver exactly what your project requires. For projects involving hazardous or difficult to reach environments, we’ve also perfected the use of robotic hydro blasting tools, giving us the productivity and power we need, even from afar.

Can Water Jetting Remove Road Paint?

Yes! AK Industrial Services’ extremely powerful ultra-high pressure water jets can cut through road paint, reinforced tape, epoxy, and line striping like butter – all without damaging the top surface of the concrete or asphalt. This means that concrete won’t need to be repaired after the paint is removed, and important features such as rumble strips remain intact.

How Does The AK Industrial Services Team Remove Membranes, Epoxies, and Other Coatings?

When membranes, urethanes, and epoxies stop doing their job, they must be removed, and the surface must be prepared for coating reapplication. Using tools ranging from hand lances, to waterjet “mowers”, to 16-ft traverse beam robots, the AK Industrial Services team can quickly and effectively remove every remnant of coating, to ensure that the surface is ready for an evenly applied new coating, for maximum service-life.

Hazardous Coating Removal of Toxic and Radioactive Materials

Ultra-high pressure water jetting is a versatile tool that’s been used in a number of industries. For clients whose projects involve high levels of contamination or radiation, the power and versatility of water jetting is unmatched. When you need fast, effective clean up or decontamination of radioactive waste and build up, or for decommissioning of components with hazardous coatings, AK Industrial Services has the solutions.

Our expertise and experience, coupled with knowledge of constantly-improving technology, enables the AK Industrial Services team to provide contractors and government agencies throughout the U.S. with safe, fast, and effective hazardous coating removal services for a wide variety of decontamination and decommissioning project applications, including

- Heat exchangers

- Pipe work

- Pressure vessels

- Runoff tanks

- Cold cutting

- Surface preparation

Effective, Thorough Cleanup of Toxic and Radioactive Materials

AK Industrial Services offers clean-up, decommission, and decontamination services for projects involving radioactive or toxic waste.

Clients are often concerned with not only the effectiveness of water jetting for nuclear decontamination, but with maximizing efficiency and reducing waste. Our water-jetting tools direct water precisely, increase repeatability, and minimize waste – making cleanup easier and more cost effective. Our team’s experience with cleanup of toxic and radioactive materials, coupled with our consistent equipment improvement, is your assurance that we can successfully remove toxic or radioactive coatings for your projects.

We use manual as well as robotically-operated water jetting tools – making it possible to decontaminate, decommission, and remediate highly irradiated environments.

The Essential Water-Jetting and Radioactive Decontamination Solutions You Need

- Ultra-high pressure (UHB) water jetting for radioactive build up

- Access cuts into radiological waste storage tanks

- Hydroscarification on fuel rod containment ports

- Non-toxic chemical solvents

- Fixed lance tubular cleaning

- Combined hydro lasing with radiological detection for thorough decontamination

- Precision spot cleaning

For more information on Coating and Membrane Removal, contact us today!

less