Projects

Oil City PA Plant Decommissioning

Location: Oil City, PA

Owner: Sasol

Overview:Project Overview AK Industrial Services was hired by the Owner to cut access holes in existing tanks at a facility that was in the process of being decommissioned. AK utilized abrasive water jet cutting, also known as cold cutting, to cut the holes as directed. Cold cutting provided a safe method of entering a potentially MORE >

Services:Mobile Water Jet Cutting

Markets:

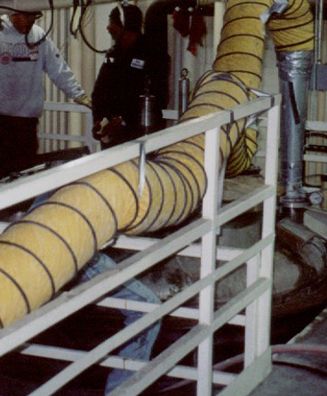

Tank Abrasive Jet Cutting at Tennessee Valley Authority Facility

Location: New Johnsonville, TN

Owner: Tennessee Valley Authority

Client: Petroleum Recovery Services

Overview:AK Industrial Services was hired by the General Contractor to cut equipment access holes in existing above ground storage tanks at a facility owned by the Tennessee Valley Authority (TVA). MORE >

Services:Mobile Water Jet Cutting

Markets:

Ship: M.V. Sun – Abrasive Jet Cutting

Location: Brooklyn, NY

Owner: G. Marine

Client: M.V. Sun

Overview:AK Industrial Services cut access holes in the hull of the M.V. Sun, a ship in Brookyn NY, in order to access and clean the ballast tank. MORE >

Services:Mobile Water Jet Cutting

Markets:

Irving Fuel Tank-Access Door Sheet Cutting

Location: Revere, MA

Owner: Irving Oil

Client: Phoenix Welding

Overview:The AKIS team used abrasive water cutting and doorsheet removal on an Irving fuel tank, to provide the necessary access to replace the floor. MORE >

Services:Mobile Water Jet Cutting

Markets:

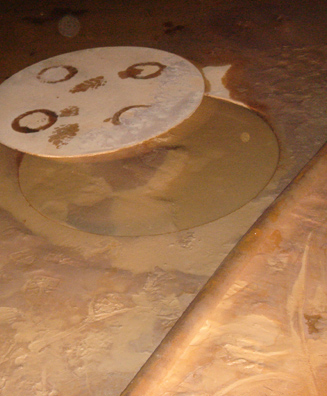

Global Oil Tank Cold Cutting

Location: Boston, MA

Owner: Global Oil

Client: Global Oil

Overview:An above-ground storage tank developed a leak in the floor, resulting in the sand below the floor becoming saturated in gasoline. The AK Industrial Services team used abrasive jet cutting as a method of "cold cutting" to safely cut in an explosive atmosphere. MORE >

Services:Mobile Water Jet Cutting

Markets:

Degussa Chemical Process Tank

Location: Brighton, CO

Owner: Degussa Construction

Client: Degussa Construction

Overview:Using abrasive water cutting, the AK Industrial Services Team removed the top of a process tank at Degussa Chemicals in Brighton, Colorado, and cut out the solidified material within the tank. MORE >

Services:Mobile Water Jet Cutting

Markets:

Benecia Bridge

Location: Martinez & Benecia, CA

Owner: CalTrans

Client: Kiewitt

Overview:AKIS performed abrasive jet cutting to a drive shoe for removal from a crippled drilled shaft casing at Benecia Bridge in California. MORE >

Services:Mobile Water Jet CuttingDrilled Shaft Anomaly Removal

Markets: